20 years of undefeated success

New Energy Battery Parts

Why our customers choose us for their stamped battery components?

Precision, groundbreaking, and economical battery technology is imperative as the world transitions to a renewable energy economy. The custom parts of batteries and energy storage systems are absolutely necessary to help reduce the influence of pressure and heat, and get the desired result...

Automotive Stamping Parts

At DERSUN, we can provide custom stamping services and products for different automobile parts, such as automotive seat, brake disc, automobile chassis, automobile door lock, precision bracket, door chain system, and the internal structure under the technical certificate of IATF16949.The automotive industry heavily relies on its customers...

Electrical Stamping Parts

Design the tools for precision connector shell, terminal, connector, PIN, hardware, and precision drawing parts.

With our intelligent and experienced engineering teams, together with complete and powerful equipment, we are able to design small stamping parts for electronics...

Industrial Stamping Parts

The products are widely used in the industry, such as metal frames, contacts, rivets and other metal stamping parts. We provide a full service from design to processing, we specialized in development of the simple one-step to complex multi-step progressive tools, which according to customer different requirements...

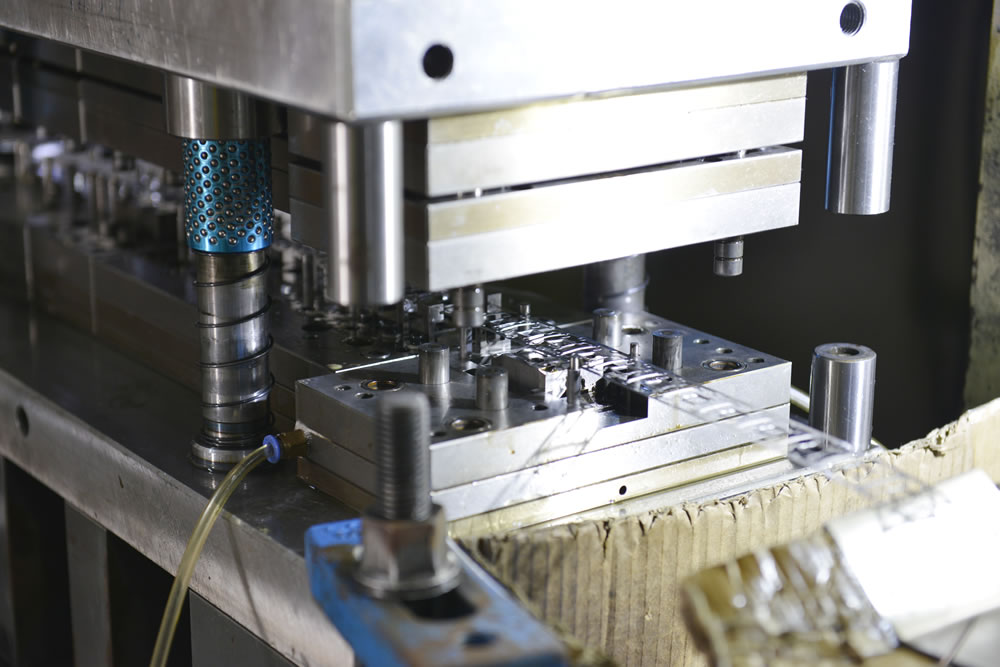

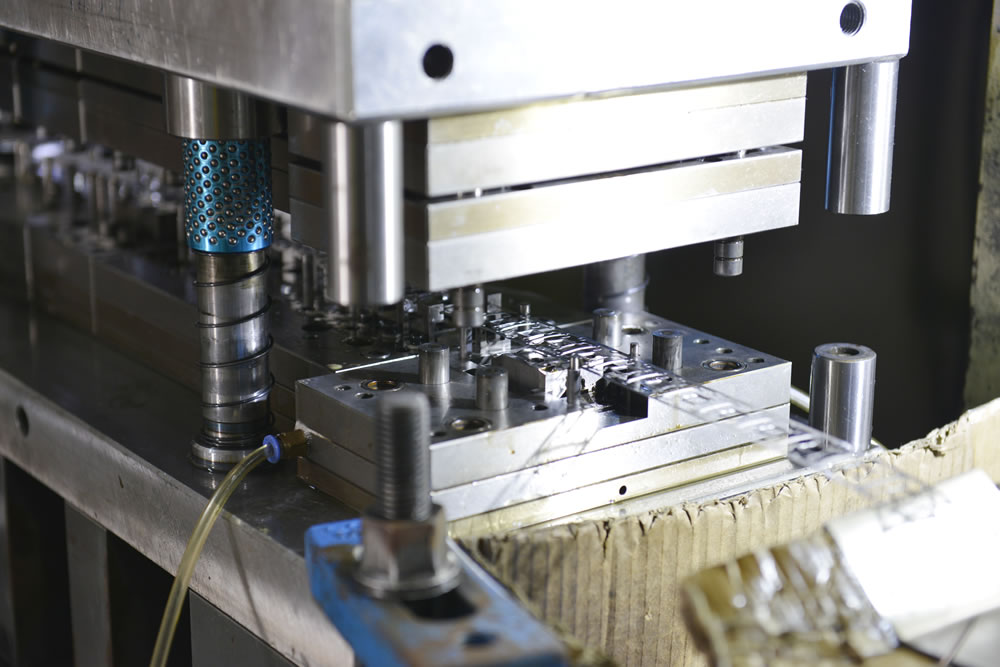

Stamping Dies

There’s wide application of stamping dies with various field in automobiles and electronics industry, such as poles & covers for new generation battery, automobile internal structure components, electrical parts, frames, terminals, shells…

The stamping dies has high requirements of the structural strength, stiffness, surface hardness...

Die Components

Do you need die components for replacement of the stamping and injection tools ? Dersun is well-known as the best maker for the high precision custom parts in the world. We’re specialized in optimizing the skills and knowledge of an experienced manufacturing team with the state-of-the-art equipment. All the custom die tooling and its die components will be sent to clients in time...

ABOUT STAMPING PRODUCTION

Stamping Production

Dersun produces a variety of high precision metal stamping parts which made from copper, copper alloy, brass, stainless steel, pre-plated materials. We produce stamping components such as covers & poles for new energy batteries; hinges systems, fasteners, brackets for automotive parts; electronic shielding components, lead frames, pins, terminals, wire and cable connectors for electrical industry and more.

Dersun value every customer’s need, from initial contact to on-time delivery of completed solutions, fully satisfying all customers’ needs with superior product quality as well as customer service.

DERSUN

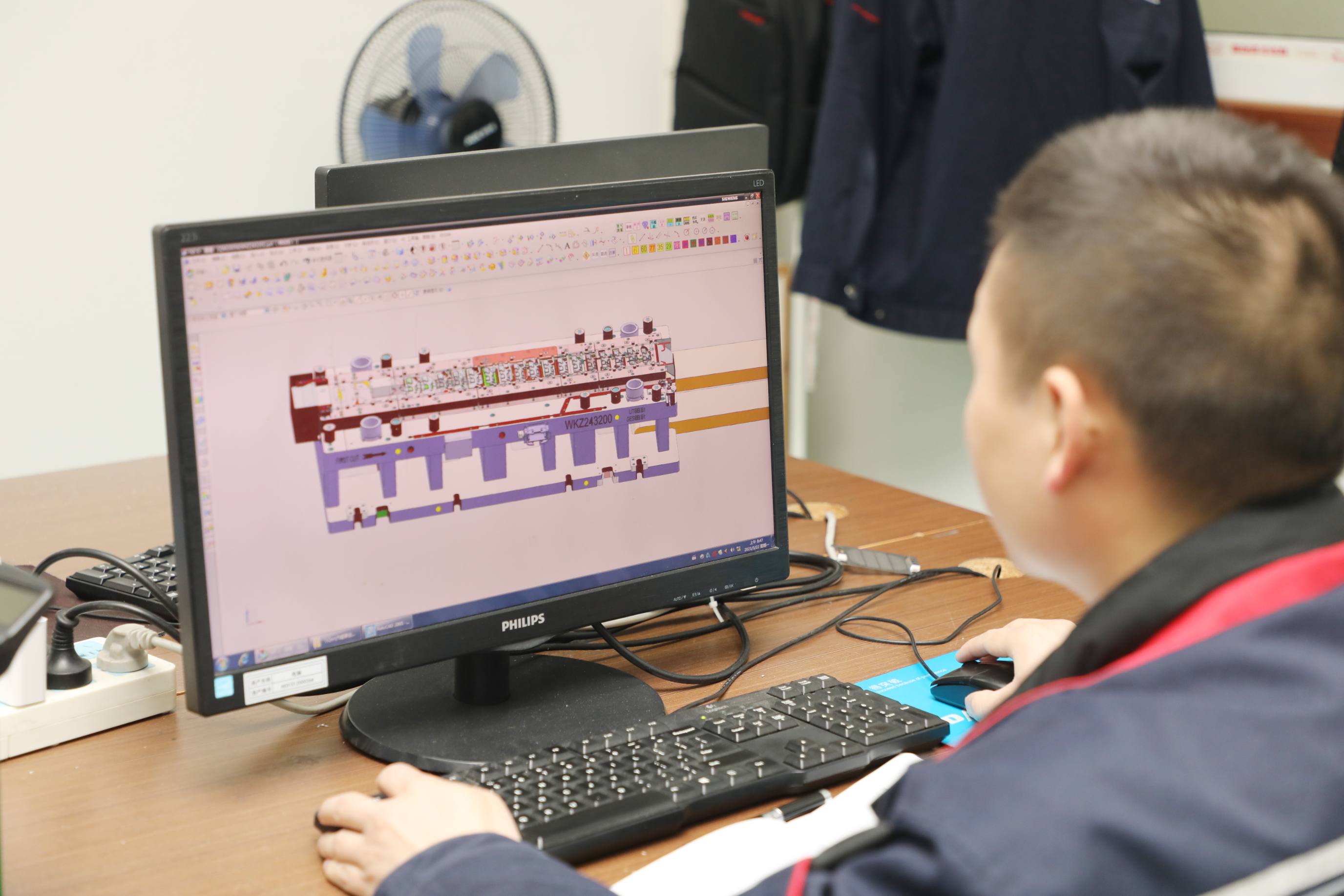

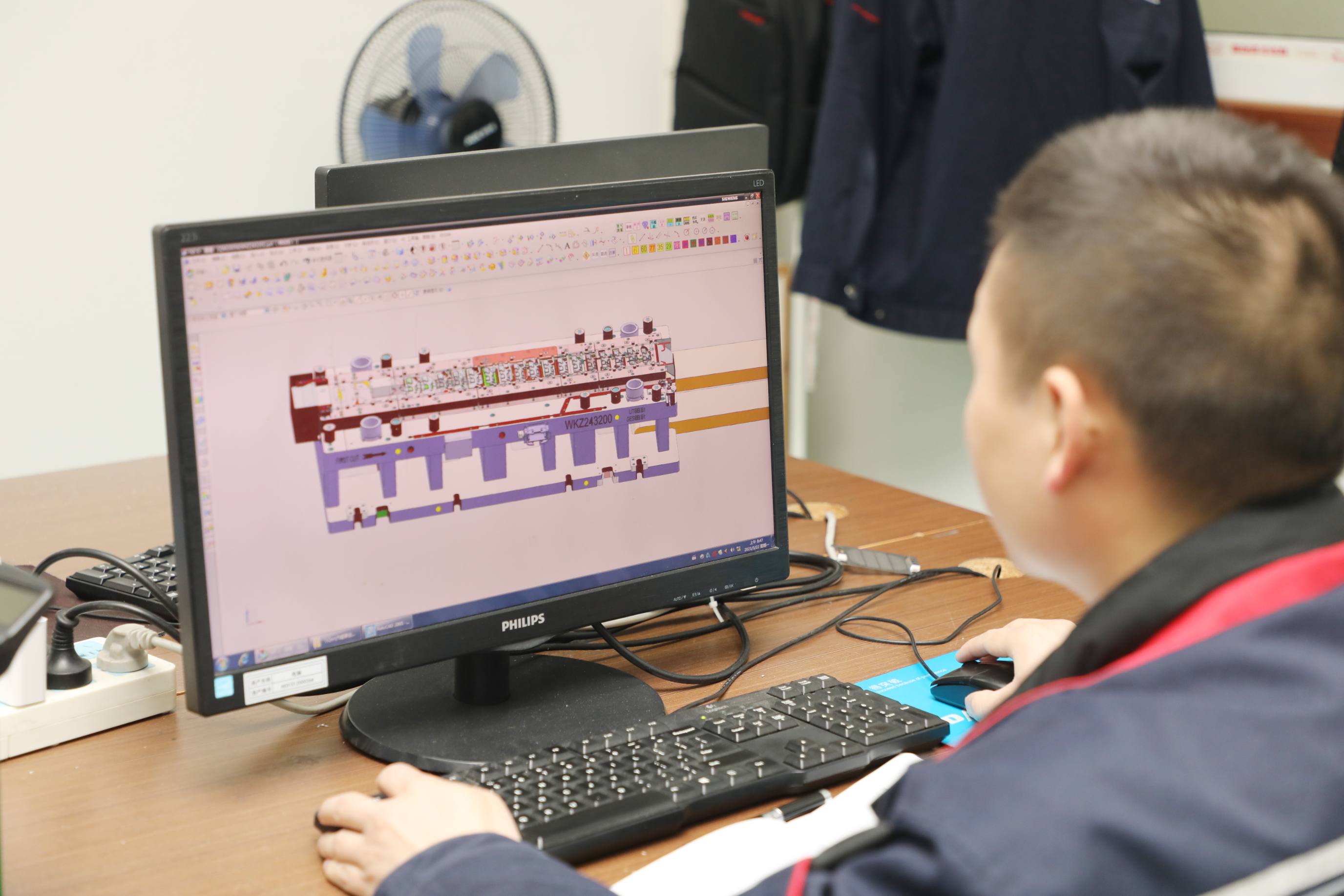

In-house Tool Shop

Dersun designs, build, assemble, and tryout all of our own high precision stamping dies in-house, which allows us for more control over the production process and allows for tooling issues to be resolved quickly and it helps reduce cost, improve quality and generate faster turnaround times.

NUMBERS SPEAK

Easy Way to Collaborate

Our Company

GET A QUOTE

Request a Quote

Certifications

Certificate of Registration

Environmental Management System Certification

Quality Management System Certification

Our Company News

How to tell a stamping die story without any drawings?-

How to tell a stamping die story without any drawings?

Telling a stamping die story without any drawings can be challenging, but it is possible to convey the key details using descriptive language. Here’s an example of how you might tell a stamping die story: “Once upon a time, there was a stamping die t...

Some reasons you might want to take a look at getting some maintenance done on stamping dies.-

Some reasons you might want to take a look at getting some maintenance done on stamping dies.

Stamping dieis an important tool in the manufacturing process of many products. Time flies,they will be teared and worn, which will affect their performance and longevity. Here are some reasons that you want to consider getting maintenance done on yo...

What does stamping parts used on battery?-

What does stamping parts used on battery?

Stamping parts can be used in various components of a battery, including the casing, terminals, and other small components. Here are some examples: Battery Casing: The outer casing of a battery is often made of stamped metal parts to provide durabili...

What is the advantadge of stamping parts?-

What is the advantadge of stamping parts?

Stamping is a manufacturing process that involves shaping and cutting metal sheets into desired shapes and sizes using a stamping press. The main advantage of stamping parts is that it allows for the efficient mass production of complex, high-precisi...

All of our stamping dies have full feed lines-

All of our stamping dies have full feed lines

A full feed line is a type of our stamping die design, where raw material is fed through the die in a continuous strip, with the stamping operation occurring at each station along the die. This is in contrast to a partial feed line, where the material is fed through the die in individual sections.

What kind of materials we make stampings-

What kind of materials we make stampings

Sheet metal stamping parts can be made from a wide variety of raw materials,like common metals used for stamping work including aluminum, copper, copper alloy, brass, steel, stainless steel,coated materials and so on.

Practical suggestion for stamping die running-

Practical suggestion for stamping die running

1.Regular Maintenance: As mentioned earlier, regular maintenance of stamping dies is essential to ensure that they are running at their best. This includes cleaning, lubricating, and inspecting the dies to identify any potential issues.

Do you want to get a stamping die preventative maintenance through us-

Do you want to get a stamping die preventative maintenance through us

Preventative maintenance on stamping dies is an important aspect of ensuring that your manufacturing processes run smoothly and efficiently. By regularly inspecting and maintaining your stamping dies, you can identify and address any potential issues before they cause downtime or quality problems.

What do we need to keep to find out problem area on progressive die?-

What do we need to keep to find out problem area on progressive die?

To find out the problem area on a progressive die, you need to keep a few things in mind: 1.Inspection Records: Keeping inspection records of previous die inspections can help you identify any changes or damage that has occurred since the last inspection. 2.Production Data: Production data such as the number of parts produced, the time taken to produce them, and any issues that arose during production can help you pinpoint potential problem areas. 3.Visual Inspection: Conducting a visual inspection of the die can help identify any obvious signs of wear and tear, such as cracks, chips, or other damage. 4.Test Cuts: Making test cuts with the die can help identify any issues with alignment or wear that may be affecting the quality of the parts produced. 5.Surface Analysis: Analyzing the surface of the parts produced can help identify any cosmetic defects or issues with tolerances that may be related to the stamping die. By keeping track of these factors and regularly inspecting and testing the progressive die, you can identify problem areas and take appropriate steps to address them before they cause significant issues or downtime in production.

How to tell a stamping die story without any drawings?-

How to tell a stamping die story without any drawings?

Telling a stamping die story without any drawings can be challenging, but it is possible to convey the key details using descriptive language. Here’s an example of how you might tell a stamping die story: “Once upon a time, there was a stamping die t...

Some reasons you might want to take a look at getting some maintenance done on stamping dies.-

Some reasons you might want to take a look at getting some maintenance done on stamping dies.

Stamping dieis an important tool in the manufacturing process of many products. Time flies,they will be teared and worn, which will affect their performance and longevity. Here are some reasons that you want to consider getting maintenance done on yo...

What does stamping parts used on battery?-

What does stamping parts used on battery?

Stamping parts can be used in various components of a battery, including the casing, terminals, and other small components. Here are some examples: Battery Casing: The outer casing of a battery is often made of stamped metal parts to provide durabili...

What is the advantadge of stamping parts?-

What is the advantadge of stamping parts?

Stamping is a manufacturing process that involves shaping and cutting metal sheets into desired shapes and sizes using a stamping press. The main advantage of stamping parts is that it allows for the efficient mass production of complex, high-precisi...

All of our stamping dies have full feed lines-

All of our stamping dies have full feed lines

A full feed line is a type of our stamping die design, where raw material is fed through the die in a continuous strip, with the stamping operation occurring at each station along the die. This is in contrast to a partial feed line, where the material is fed through the die in individual sections.

What kind of materials we make stampings-

What kind of materials we make stampings

Sheet metal stamping parts can be made from a wide variety of raw materials,like common metals used for stamping work including aluminum, copper, copper alloy, brass, steel, stainless steel,coated materials and so on.

Practical suggestion for stamping die running-

Practical suggestion for stamping die running

1.Regular Maintenance: As mentioned earlier, regular maintenance of stamping dies is essential to ensure that they are running at their best. This includes cleaning, lubricating, and inspecting the dies to identify any potential issues.

Do you want to get a stamping die preventative maintenance through us-

Do you want to get a stamping die preventative maintenance through us

Preventative maintenance on stamping dies is an important aspect of ensuring that your manufacturing processes run smoothly and efficiently. By regularly inspecting and maintaining your stamping dies, you can identify and address any potential issues before they cause downtime or quality problems.